Equipment profile

- The equipment adopts one drag and one structure design, using ultrasonic welding technology, with advanced technology, reasonable structure, stable operation, convenient operation and so

- Equipment applicable material

Non-woven fabric, ultra-fine polypropylene fiber melt spray cloth, ultra-thin polypropylene melt spray cloth, sanitary gauze, calendering cloth, activated carbon cloth, filter paper and other non-woven materials can be used for mask production.

3. Applicable function of equipment

⑴Roll up material

⑵Bag nose line

⑶Molding

⑷Ultrasonic lacing

⑸Section

⑹Ultrasonic earline

⑺Automatic discharge

4. Applicable products

⑴2~4-layer flat mask (mask size 17.5*9.5 cm mask)

⑵Civilian flat masks

⑶Medical flat mask

5. Equipment functions

⑴The above functions can be obtained by using ultrasonic wave and special roller pressurization.

⑵Do not smoke, sparks, do not harm the edge of cloth, can also avoid edge.

⑶No preheating is required and can be operated continuously

⑷The knurling wheel made of special alloy steel material has the characteristics of wear resistance and long service life by special heat treatment process.

⑸Easy to operate and maintain.

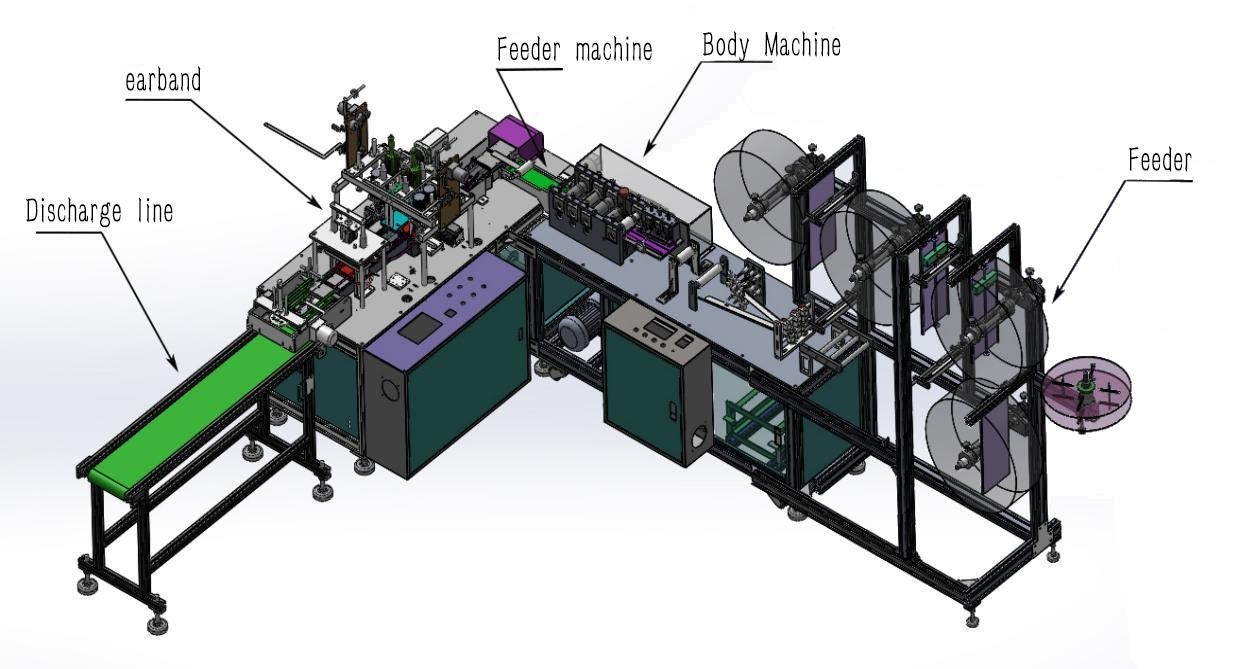

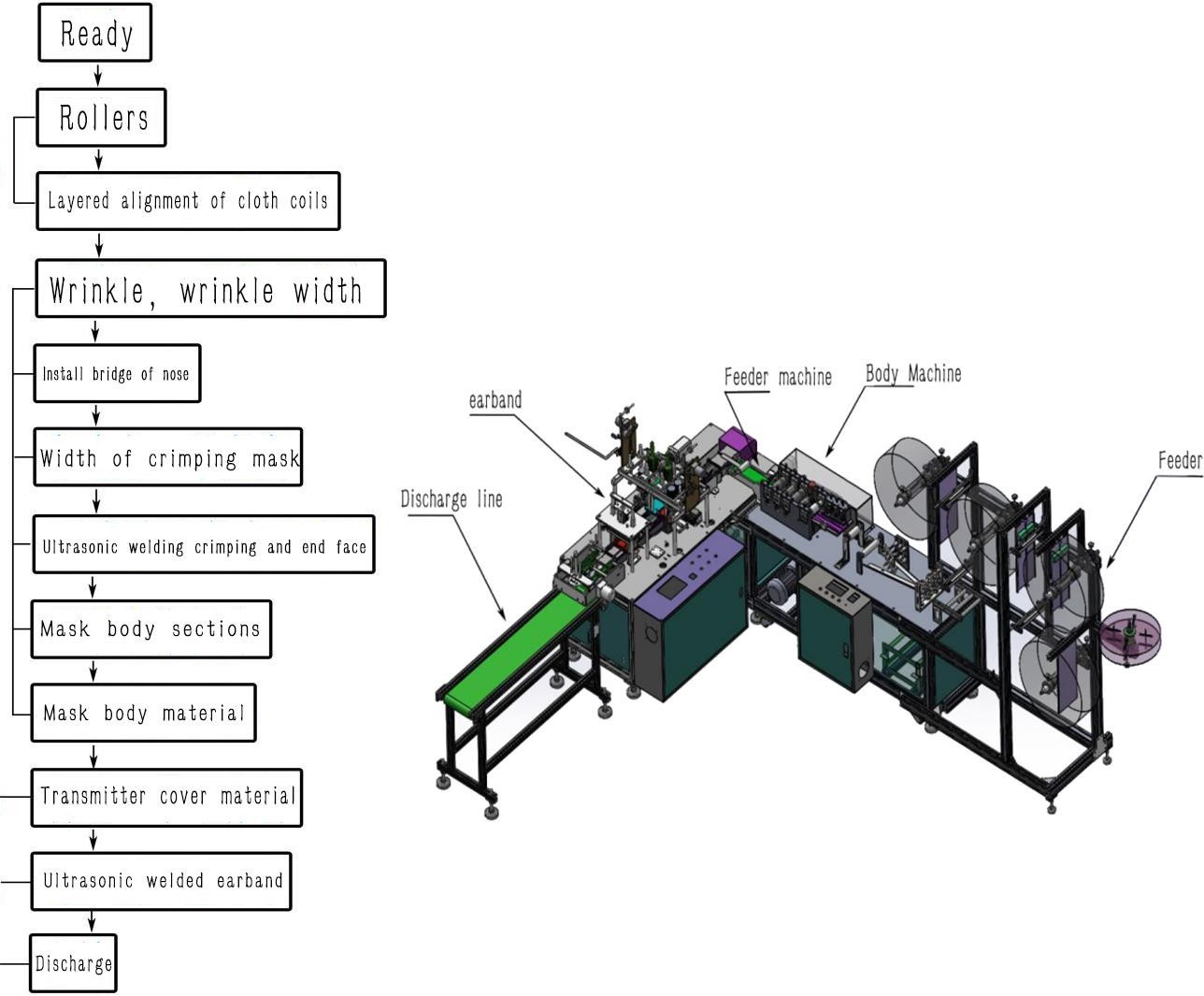

6. Composition of equipment

Composition and Function of Flat Mask:

- Feeder:Install mask non-woven fabric roll and nose wire

- Body Machine:Production of mask

- Feeder machine:Drive mask body to lower

- earband:Welded

- Discharge line:Output housing

Equipment profile

1. The equipment adopts one drag and one structure design, using ultrasonic welding technology, with advanced technology, reasonable structure, stable operation, convenient operation and so on.

2. Equipment applicable material

Non-woven fabric, ultra-fine polypropylene fiber melt spray cloth, ultra-thin polypropylene melt spray cloth, sanitary gauze, calendering cloth, activated carbon cloth, filter paper and other non-woven materials can be used for mask production.

3. Applicable function of equipment

⑴Roll up material

⑵Bag nose line

⑶Molding

⑷Ultrasonic lacing

⑸Section

⑹Ultrasonic earline

⑺Automatic discharge

4. Applicable products

⑴2~4-layer flat mask (mask size 17.5*9.5 cm mask)

⑵Civilian flat masks

⑶Medical flat mask

5. Equipment functions

⑴The above functions can be obtained by using ultrasonic wave and special roller pressurization.

⑵Do not smoke, sparks, do not harm the edge of cloth, can also avoid edge.

⑶No preheating is required and can be operated continuously

⑷The knurling wheel made of special alloy steel material has the characteristics of wear resistance and long service life by special heat treatment process.

⑸Easy to operate and maintain.

6. Composition of equipment

Composition and Function of Flat Mask:

1. Feeder:Install mask non-woven fabric roll and nose wire roll.

2. Body Machine:Production of mask body.

3. Feeder machine:Drive mask body to lower position.

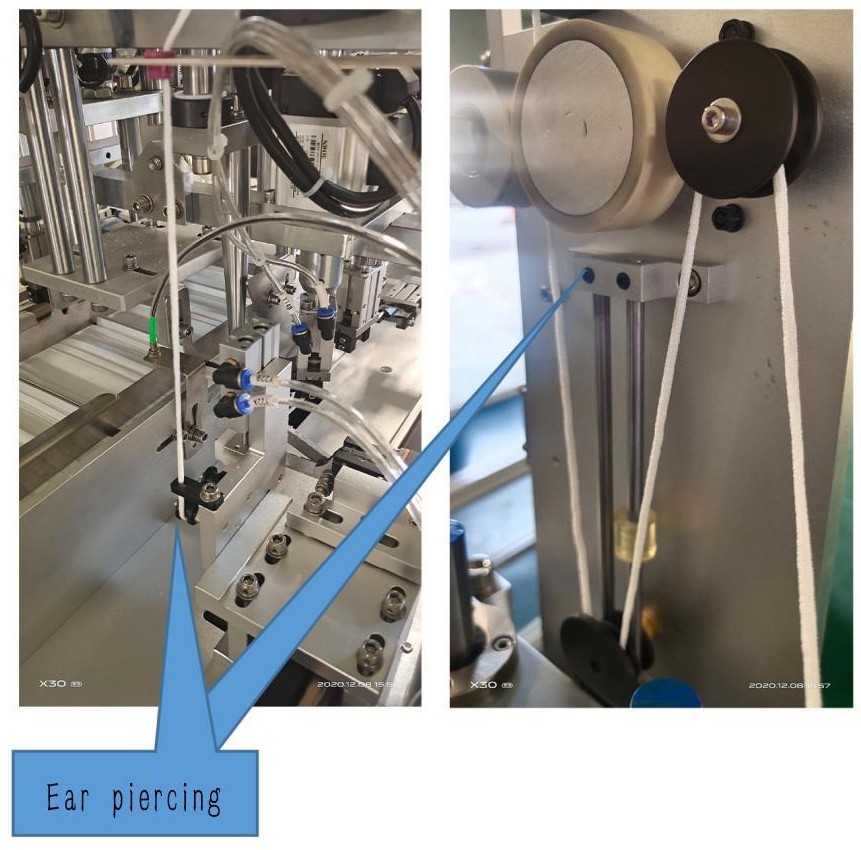

4. earband:Welded earband.

5. Discharge line:Output housing finished.

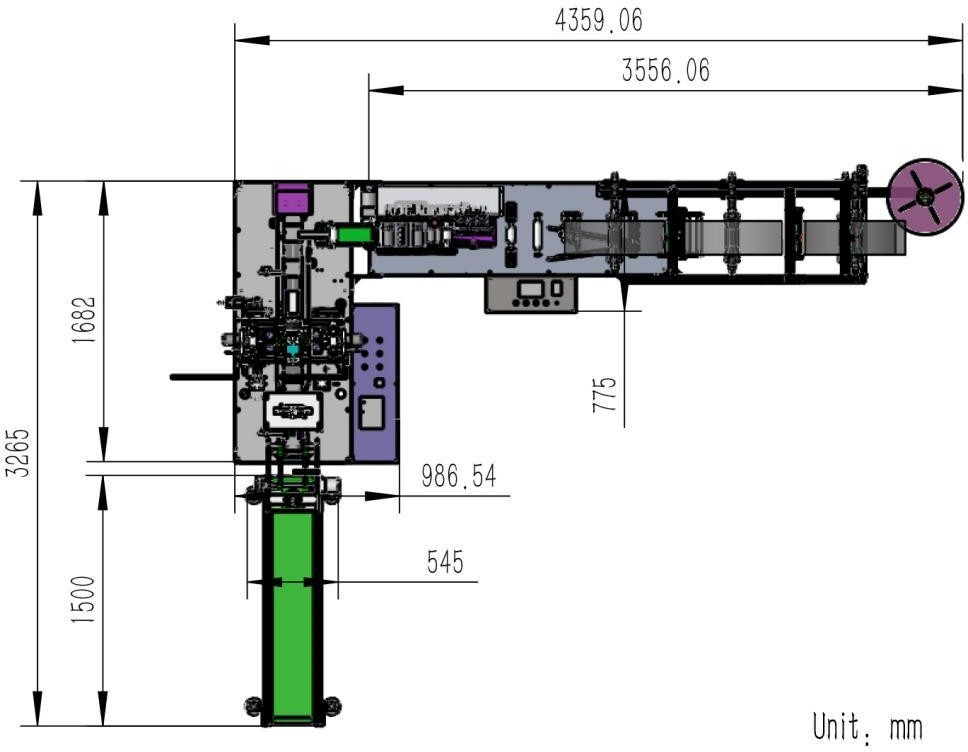

1. Equipment Size and Layout

According to the requirements of the discharge line can be placed flexibly, the main layout method is as follows:

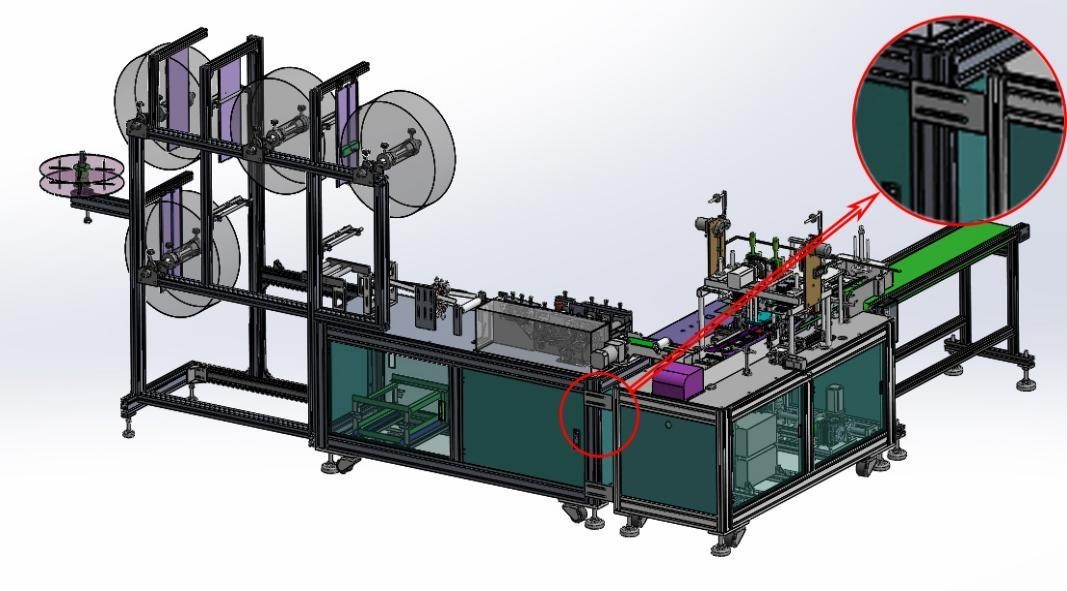

Attention to installation connection: as shown in the diagram, use angle iron to

strengthen the connection between the machine and the ear belt machine,

and place the installation position change caused by the working vibration of the machine.

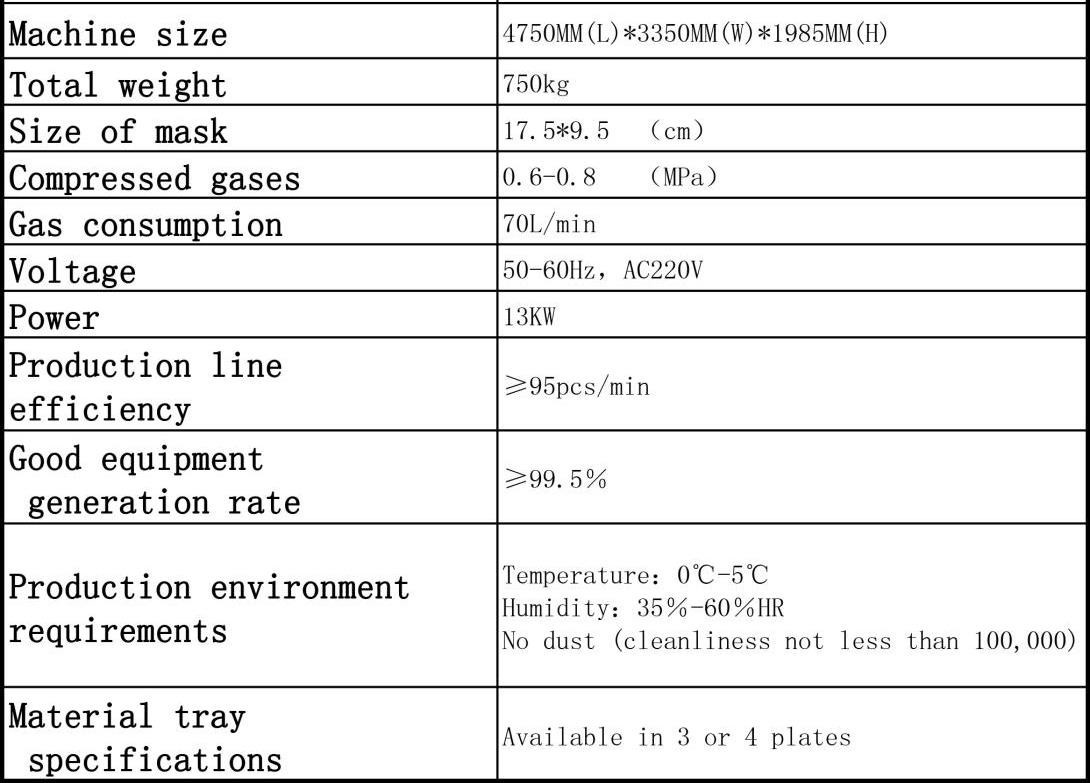

6. Main parameters of equipment (for reference only)

Operating principles 2-1.Work Process of Plane Mask Machine

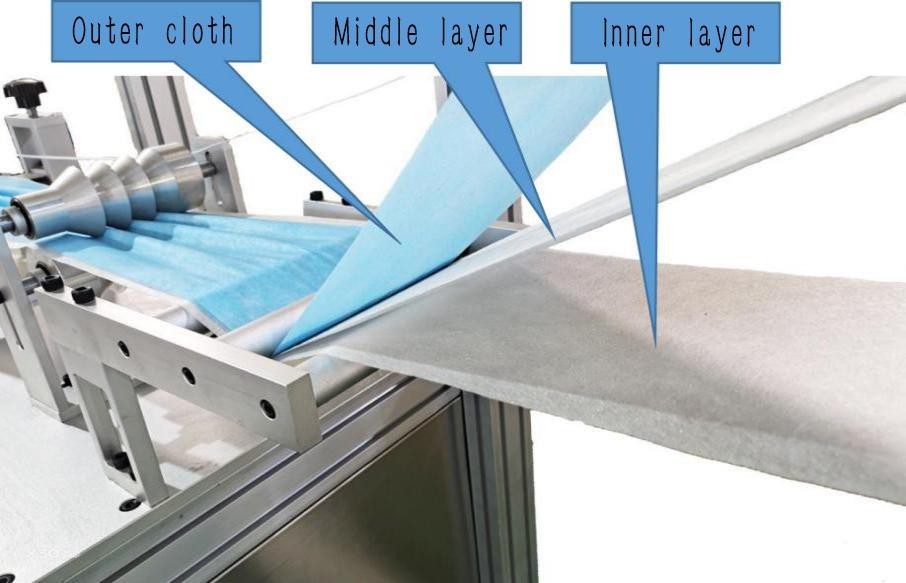

2.Feeder

Install the cloth roll in order to the feeder, up to 4 rolls of cloth can be installed. Place the nose bar roll in the nose bar roll.

Specification for mounting rolls:

- Winding diameter :φ600~800 mm Winding diameter :φ2mm

Nose wire coil outer diameter :φ450mm nose wire coil core diameter :φ110~250 mm

Installation of nose beam coil and cloth coil as shown below:

\

\

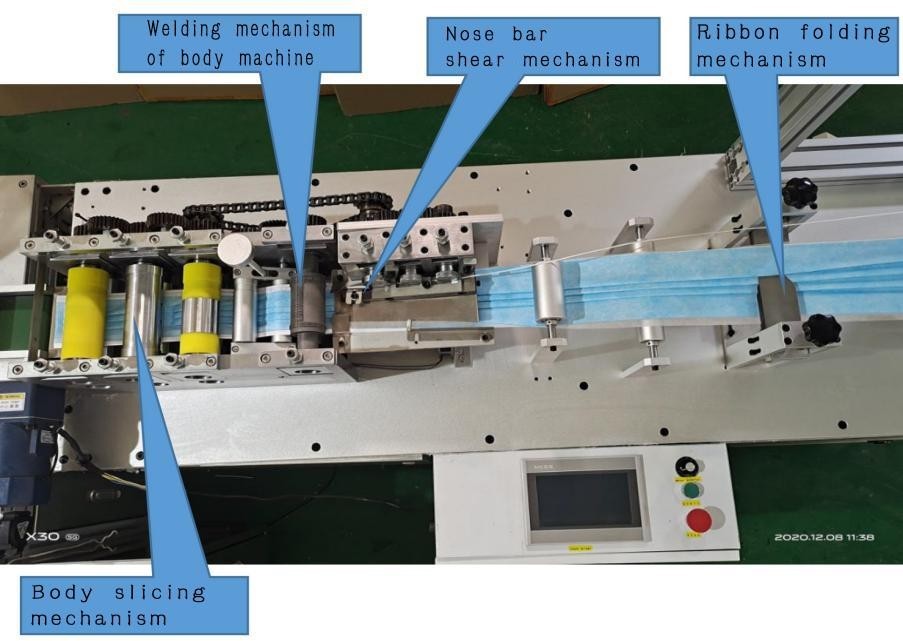

2-3.Body Machine

- Ribbon folding mechanism: folding and forming incoming materials where folding is

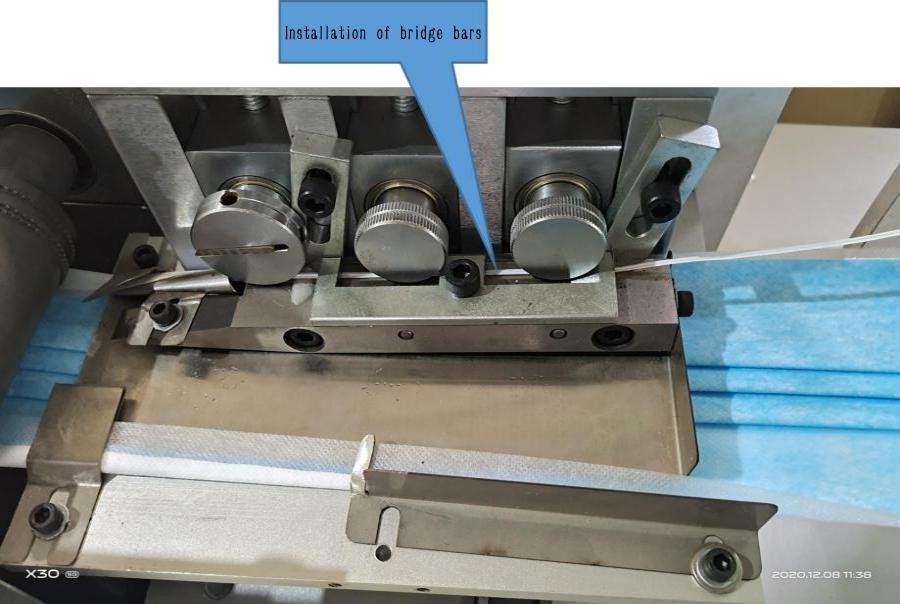

- Shearing mechanism of the nose line: direct, press the nose line, cut the nose line according to the fixed length and put it in the specified

- Body welding mechanism: fold the cloth roll according to the specified size, insert the bridge line into the cloth, weld the edge, and make the mask body of standard length through the accurate meshing of the

2-4.Ear wire welding machine

- Feeding mechanism: transport mask body material to earband welding machine receiving mask body

- Ear band welding mechanism: welding the ear wire to the position of the mask body by ultrasonic

- Discharge mechanism: orderly discharge of finished

Reviews

There are no reviews yet.